The Art of Laser Welder for Jewelry

In the intricate world of jewelry crafting, precision and finesse are paramount. The technique of laser welding has taken on a central role in the history of the jewelry industry thanks to its unique fusion of artistry and technology. The fundamental nature of jewelry creation, repair, and customization has been revolutionized by this innovative method, which is carried out using a laser welder for jewelry.

Therefore, what makes laser welding so unique? What are the benefits of lasers for the business you run?

Conquering the Unthinkable Repair Jobs

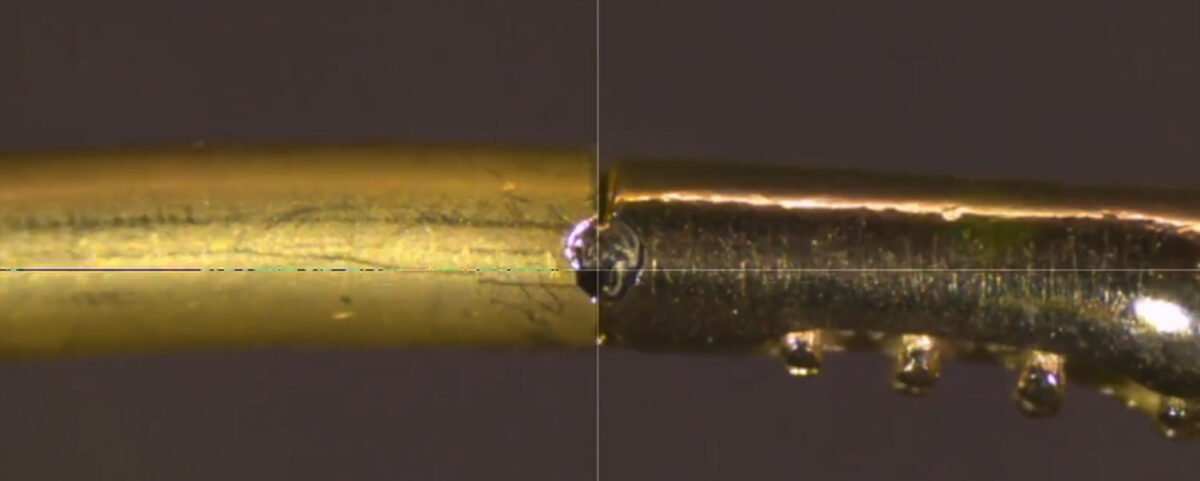

Jewelry repair laser welding has advanced the industry to new levels by enabling craftsmen to do repairs that were previously thought to be unfeasible. Due to the possibility of damage during repair, delicate items with elaborate designs and heat-sensitive jewels used to present a challenge. Traditional soldering techniques frequently involve the use of an open flame, which can result in excessive heat that may harm intricate designs, metals, and jewels. Laser welding, on the other hand, uses a concentrated light beam to quickly melt and fuse metals together. This extreme precision guarantees that the jewelry’s surrounding areas are unaffected and maintain their integrity. With a benchtop laser welder, laser technicians can hold the piece to be welded in their fingers while welding. Repairing a complicated chain link, reattaching a small prong, or restoring an exquisite filigree is now not only possible but also achievable with the highest precision.

Precision Craftsmanship and Customer Loyalty

The benefit of laser welding jewelry is creating precision craftsmanship and building customer loyalty. Craftsmanship is the soul of jewelry making, and precision is its heartbeat. Jewelry manufacturing now benefits from an unmatched level of precision thanks to laser welding. Each piece is an elegance of symmetry and grace because artisans can smoothly combine complicated components. Clients are lured to the immaculate aesthetics and the painstaking attention to detail that only laser welding can accomplish, and this precision converts to customer loyalty. The emotional bond between the customer and the jewelry item is strengthened when a ring is resized without revealing any seams or damage. It demonstrates your creativity and technological awareness. Because of this, your customers are in awe of your talent and expertise as a jeweler, goldsmith, and platinumsmith. Your reputation as an expert who can handle challenging or “impossible” repair problems helps to inspire confidence in your clients and, as a result, comfort.

Speeding Up Time and Elevating Productivity

Laser welding has become a time-saving wonder in today’s fast-paced, time-constrained environment. Traditional soldering techniques may require lengthy setup, heating, and cooling times, which can reduce production. However, laser spot welding dramatically reduces production times. There is no need to apply a protective fire coating to the repair item and no need to pickle the item. The focused laser beam swiftly melts and fuses metals with pinpoint accuracy. What used to take hours can now be completed in minutes, allowing artists to concentrate more on creativity and design, thereby accelerating the entire jewelry-making process.

A Beacon of Innovation and Craft Integration

The craft of laser welding is a shining example of innovation, merging time-honored craftsmanship with cutting-edge technology. Although the laser is a marvel in and of itself, the artisan’s expertise is still paramount. A thorough knowledge of metals, a grasp of heat dynamics, and exact equipment control are necessary for laser welding. The laser welder for jewelry transforms into a contemporary sculptor, sculpting metal and giving creations life. Technology and craftsmanship work in harmony to create gorgeous jewelry items that engage the senses. In order to obtain the desired results, jewelry designers and artisans must employ their skills to precisely control the laser, making decisions about the amount of heat applied, the speed of the welding process, and the overall technique.

Although there is still plenty to learn about techniques, lasers are quite user-friendly. Create your own technique and impart some of your knowledge to others. Jewelry laser welders are a major investment for most jewelry repair shops and jewelry manufacturers. Allow lasers to assist you in enhancing your brand, your company, and ultimately your bottom line.