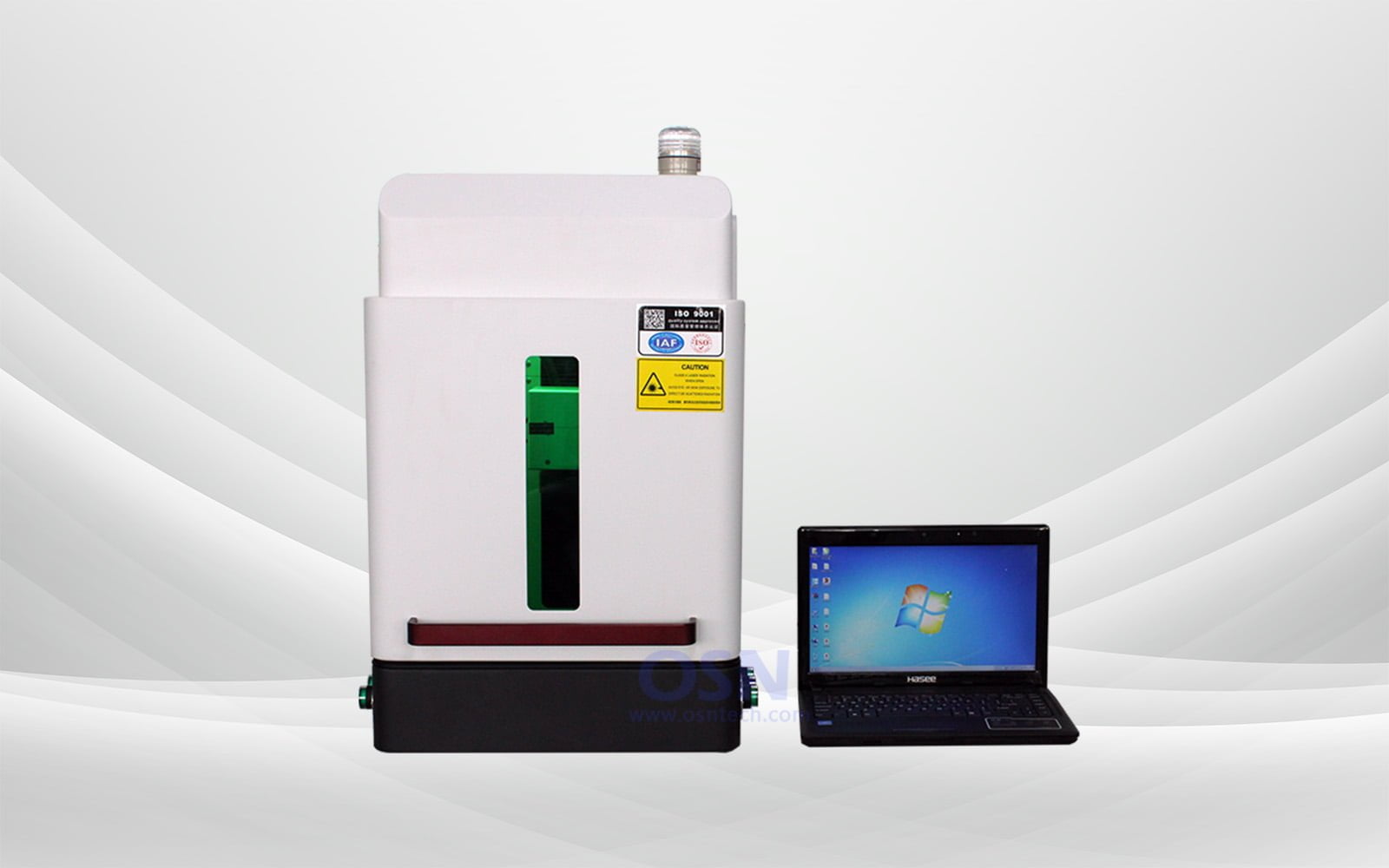

Portable Spot Jewelry Laser Welder

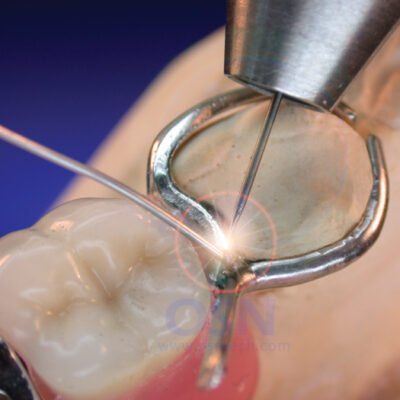

Stable power, easy to use, and simple to maintain, the jewelry laser welder is ideal for high-precision processing of metals, like gold, silver, stainless steel, titanium, and so on. Therefore, this machine can be suitable for welding jewelry, dental welding, medical soldering, and eyeglass frame repairing. The ergonomic and portable design makes the portable laser welder compact and space-saving. Thanks to the microscope and integrated screen, the laser welding process can be viewed simultaneously, all welding parameter setting and spot positioning can be realized easily. With the most efficient cooling system that allows for reliable operation, this jewellery laser welding machine enjoys its worldwide hot welcome. A gas protection device can be installed for better welding quality requirements, argon and nitrogen are generally suggested.

OVERVIEW

HD Binocular Microscope

Equipped with the crosshairs binocular microscope, the cross cursor center and the laser spot center are adjustable in alignment. Viewing and operating simultaneously for better micro laser welding.

Integrated Colorized Screen for Setting & Display

One touch screen can realize welding parameter adjustment, laser soldering process observation, and laser spot positioning. Users can adjust the current, pulse width, and frequency, the operation much easier.

More Features

SPECIFICATIONS

Jewelry laser welder parameters

| Model | PS60/ PS100/ PS150 |

|---|---|

| Laser Power | 60W/ 100W/ 150W |

| Laser Type | Nd:YAG Pulse |

| Laser Wavelength | 1064nm |

| Impulse Energy | 60J/ 80J/ 100J |

| Pulse Frequency | 0.5-20Hz |

| Pulse Duration | 0.2-20ms |

| Focal Spot Diameter | 0.2-3mm |

| Laser Output Power | 60W/ 100W/ 150W |

| Operate System | Micro-Touch Screen Control |

| Observation | HD Microscope & CCD Integrated |

| Cooling Method | Built-in Air-cooled Integrated Water Tank |

| Power Consumption | <2KW |

| Operating Temperature | <30℃ |

| Machine Dimensions | 510mm(L)*295mm(W)*395mm(H) |

| Weight(N.W.) | 28KG |