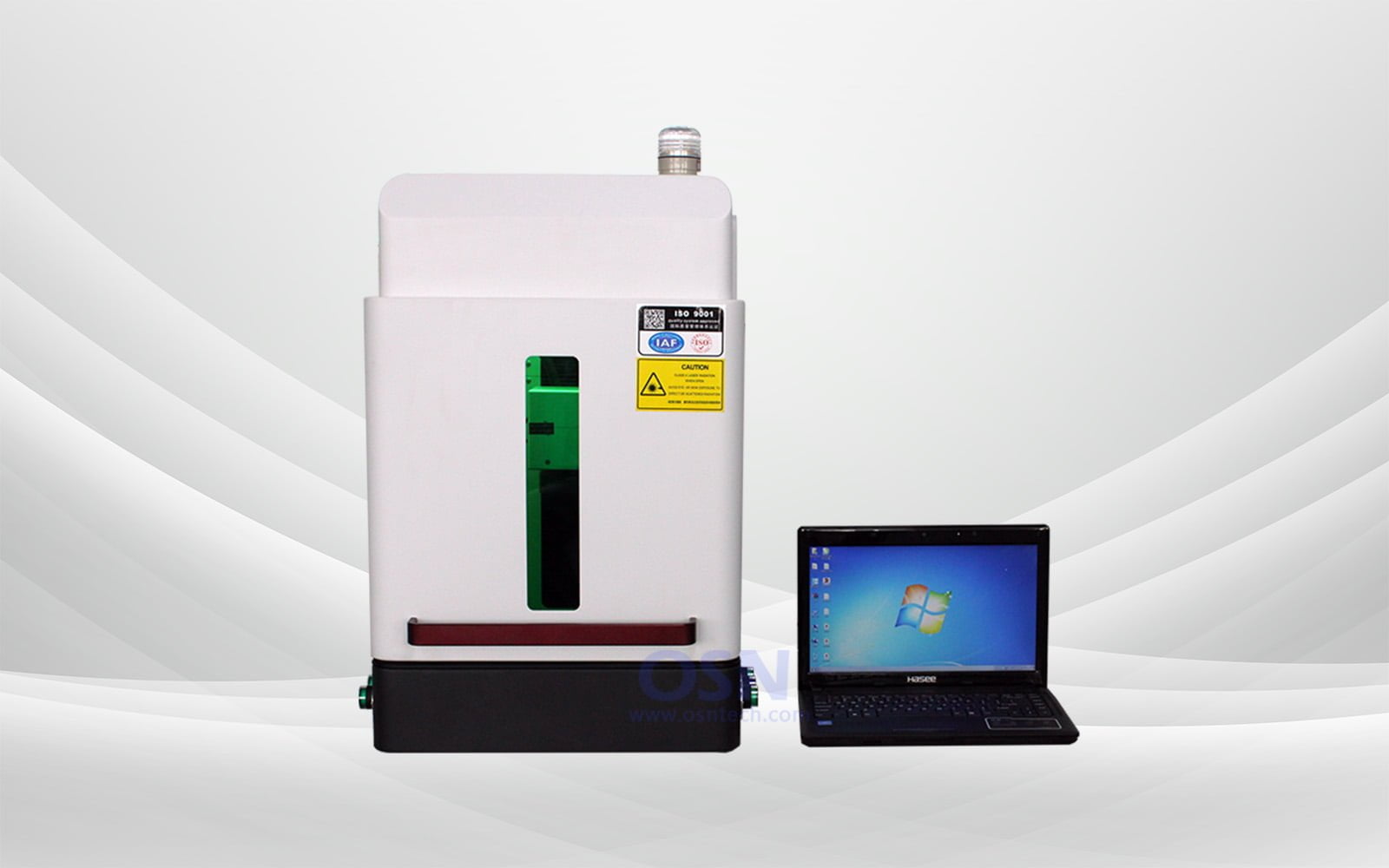

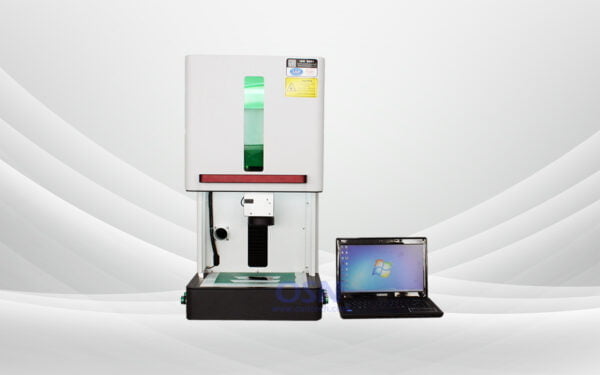

Machine de marquage laser

OSN LASER offers a wide range of laser marking machines designed for marking components, parts and products. As a professional laser marking machine manufacturer, our laser marking systems are comfortable, simple, safe to use, and an ideal solution for Any Part marking, there are no consumables and no maintenance required. And it is a high-speed, non-contact process. Our laser markers come in various wavelengths to suit the different products and their materials, according to the wavelength, the machines are divided into fiber laser marking machine, UV laser marking machine and CO2 laser marking machine.

Fiber laser marking machine stands as a symbol of innovation and efficiency, which has emerged as a game-changer in the field of product identification and traceability. This innovative equipment offers a exceptional balance of speed, accuracy, and versatility. The fiber laser marking machine has developed into an essential tool for producing high-quality, permanent markings on a variety of surfaces, regardless of whether you work in the jewelry, automotive, electronics, medical, eyewear or any other industry.

The UV laser marking machine utilizes the advantages of the ultraviolet (UV) light’s powerful properties, this incredible piece of equipment is made to meet the needs of sectors that demand superior, non-intrusive marking solutions for fragile and sensitive materials. Ranging from medical equipment to glass, lenses, and semiconductors.

Utilizing the power of carbon dioxide (CO2) lasers, the CO2 laser marking machine is designed to deliver precise markings on a diverse range of non-metallic materials. The machine can be used on a wide range of materials, including wood, glass, acrylic, paper, leather, and various plastics.

Laser Marking Definition

Laser marking is a versatile and precise technology used to create permanent markings on a variety of materials. Due to its speed and reliability, we advise using laser marking for the majority of marking applications.

What Is Laser Marking?

Laser marking utilizes a high-powered laser beam and creates marks on parts and products by melting their surface. These marks could be in the form of text, images, barcodes, numbers, or other identifiers.

In industrial and production operations, laser marking is a precise and versatile technique used for purposes like product branding, traceability, personalization, and aesthetics. It has a number of benefits, such as high precision, longevity, and versatility in marking a variety of materials, such as metals, plastics, ceramics, glass, and more.

How Does Laser Marking Work?

Laser marking works on the principle of localized material ablation that a powerful laser beam is used to selectively remove material off the surface of an object to create permanent marks. One feature unites all laser marking techniques: the laser beam is pulsed, providing quick bursts of energy at certain times. The material surface reflects the majority of the beam’s energy, but it also absorbs some of it and turns some of it into heat. Enough energy must be absorbed by the material for laser marking to take place in order to melt its microsurface and cause it to expand.

The material’s temperature rises as heat is generated from the energy of the beam. The surface becomes pliable at such a high heat, allowing it to change shape.

Various Metals’ Melting Points

| Material | Melting Point |

|---|---|

| Carbon Steel | 1415—1530°C |

| Aluminum 380 | 536°C |

| Aluminum 6061 | 580°C |

| Lead | 325°C |

| Stainless Steel Grade 304 | 1400—1450°C |

| Stainless Steel Grade 316 | 1375—1350°C |

| Magnesium | 645°C |

Localized changes take place on the surface as the material melts and cools down in milliseconds. Surface irregularity varies and leaves permanent marks.

You can also view free educational movies created by the MIT if you want to learn more about the physics underlying laser technology.

Is Laser Marking Permanent?

Yes, laser marking is considered permanent. This featured performance is one of the key advantages of laser markings. Unlike other types of marking, such as inkjet printing or labels, which might fade, wear off, or be readily erased, laser markings are deeply etched or engraved into the surface of the material. They are consequently very resistant to:

● Abrasion: Even in high-friction conditions, laser marks are resistant to being scratched or worn away.

● Chemicals: Laser marks are often resistant to contact with a variety of chemicals, such as acids and solvents.

● Environmental Considerations: They are resilient to UV light, moisture, and temperature changes.

● Modification: Without causing harm to the underlying material, it can be hard to change or delete laser markings.

Due to its durability and resistance to external influences, laser marking is widely utilized in fields where long-lasting, legible marks are required, including aerospace, automotive, electronics, and medical. It is a reliable process for branding, personalization, and traceability of products that guarantees the marks are identifiable and permanent for the duration of the product’s lifecycle.