Soudure laser bijoux, gravure & Coupe

Since a few years ago, fiber laser jewelry has been used by manufacturing and retail jewelers. And it has allowed them to provide the highest level of quality, craftsmanship, and service to their customers, instead of utilizing traditional hand tools like hammers and wood carving knives. Among the lasers, laser welding, laser engraving, and laser cutting are the most common laser technologies used on jewelry.

Laser Welding for Jewelry

Every priceless work of art requires a silversmith, goldsmith, or metalsmith who has the appropriate equipment for the job at hand. Welding is one of the tasks they need to do during the process of jewelry production, which involves designing jewelry utilizing noble metals. The art of welding was improved from culture to culture, generation to generation. The introduction of rapid prototyping technology greatly shortens the time from jewelry design to making the original, especially the laser soldering jewelry, which can be used to resize rings and bracelets, repair prongs, fill porosity, and repair earrings & manufacture.

Laser welding makes it possible to join together the precious metals and a variety of other alloys, which is strong even in areas where traditional joining techniques are challenging to achieve. It will be considerably simpler to complete thorough repairs to jewelry without removing the pieces that decorate its basic structure by producing a very high temperature in a small and precise area using a laser beam that is finely focused. The spot laser welding machine in this instance enables jewelers to consistently complete jobs that were previously either impossible or would take too much time.

Since laser welding machine jewelry provides a precise, localized pinpoint of heat that greatly reduces the risk of damage to the jewelry, it has evolved into a necessary tool for jewelers doing jewelry repairs as well as helping with jewelry designs.

Samples

Below are samples of jewelry laser welding applications

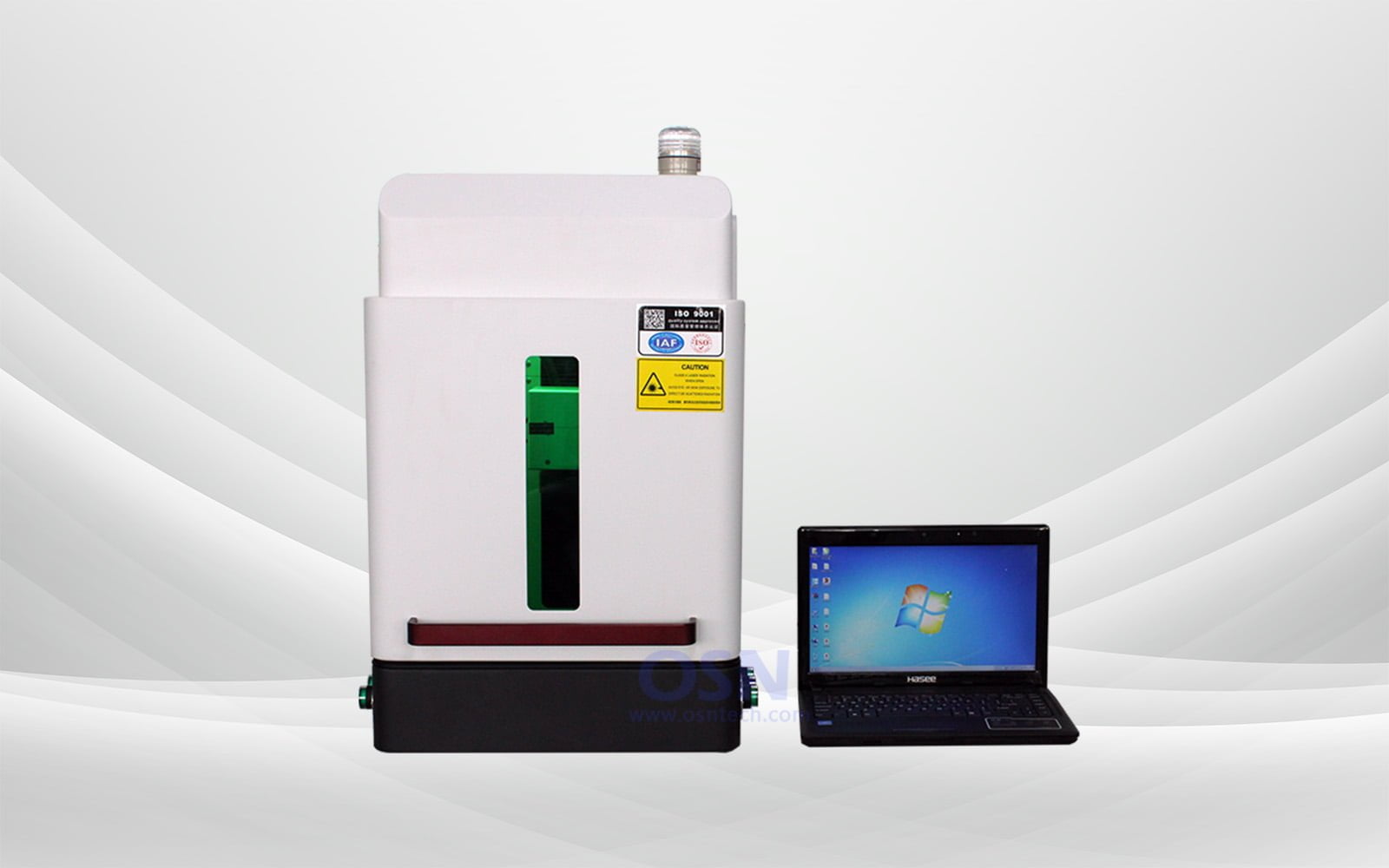

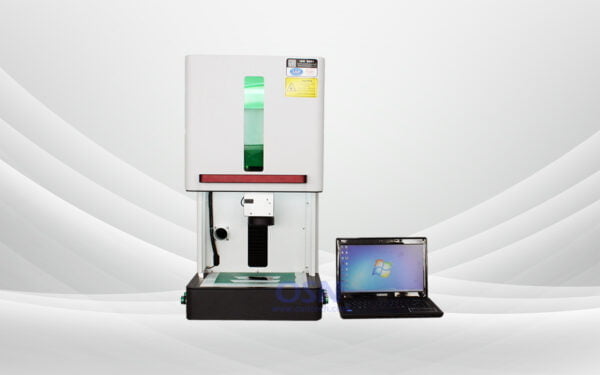

Best laser welding machine for jewelry

Laser Engraving for Jewelry

A characteristic mark can be often noticed in almost all of the jewelry in your collection, which often serves as a key indicator of details like the metal’s chemical composition, the name of the manufacturer, the place of origin, the date of production, and/or other distinctive symbolic sign.

Additionally, customers often ask to have their customization engraved on the jewelry when they purchase it. This personalization can be in the form of a message, name, date, or a variety of other things.

Traditional engraving techniques can still create such distinctive marks on jewelry, but nowadays, aesthetics and precision are essential to jewelry engraving. The laser engraving machine for jewelry is computer-controlled and provides a non-contact, abrasion-resistant, permanent laser marking on the jewelry surface. Only a tiny amount of the metal will be vaporized by the laser metal engraving machine for jewelry, thus, maintaining the jewel’s weight and worth. Any ring, bracelet, or piece of jewelry in a circle can be easily personalized to stand out both inside and outside of the circle. The jewelry metals, including gold, silver, and any alloy, can be engraved.

For the jewelry in circles, like rings and bracelets, the marking process will need the help of the rotary device. The circle diameter is adjustable to the max. 69mm. The bigger diameter jewelry can be supported by our other type of rotary device.

Samples

Below are samples of jewelry laser engraving applications

Best laser engraving machine for jewelry

Laser Cutting for Jewelry

Jewelry making as a decorative art has been around for thousands of years, as every business person knows, a unique selling point is everything when it comes to success. So jewelry designers and manufacturers are continually looking for reliable solutions for cutting precious metals to create unique pieces that appeal to customers, and differentiate you from competitors. Laser cutting is excellent for jewelry cutting applications because it creates fantastic shapes with superior edge quality, far better than what the traditional cutting methods offer. Laser cutting is the best new technology solution to enhance your ability to provide your clients with the highest level of quality, craftsmanship, and service.

Safety should be the primary concern for anyone who’s active in operation, the laser cutting is non-contact cutting, and it’s one of the safest ways to cut jewelry with risk-free. Laser cutting can also offer more accurate, precise, efficient, and customized cuts in any type of shape or design you want. There is no direct contact with the workpiece and the laser focuses heat on a small area, so it is a low likelihood of contaminating and deforming the materials. Laser cutting machines are relatively expensive these days, for jewelry cutting, generally, laser marking machines are recommended for their same cutting results and low cost. Functioning as a jewelry fiber laser cutting machine, it can achieve the whole jewelry laser cutting during production, and make jewelry that is functionally sound, aesthetically appealing, and professional looking.

Samples

Below are samples of jewelry laser cutting applications